|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OB1 Main : Main Programme Sweep |

|

|

|

|

|

Netzwerk 1: Start measuring runtime (=LastCycle) "HMI SYS".Support.LastCycle := RUNTIME("HMI SYS".Support.LastCycle_inout); |

|

|

|

|

|

Netzwerk 2: Pulse generator "HMI SYS".Support.Sav_Clock_Byte := "HMI SYS".Support.Sav_Clock_Byte XOR "M00_Clock_Byte"; "M00_Imp_Byte" := "HMI SYS".Support.Sav_Clock_Byte AND "M00_Clock_Byte"; "HMI SYS".Support.Sav_Clock_Byte := "M00_Clock_Byte"; |

|

|

|

|

|

Netzwerk 3: CALL distributor "DI MAIN GLB"(); // Global operation mode "DI MAIN P02"(); // Main programme management P02 "DI MAIN P03"(); // Main programme management P03 // ---- "DI OUT P02"(); // Output stage P02 "DI OUT P03"(); // Output stage P03 |

|

|

|

|

|

Netzwerk 4: First cycle evaluation "HMI SYS".Support.FirstCycle_TON(IN := TRUE,PT := t#2s); "M00_OB1_FirstCycle" := "HMI SYS".Support.FirstCycle_TON.Q; |

|

|

|

|

|

Netzwerk 5: End measuring runtime (=LastCycle) "HMI SYS".Support.LastCycle_real := LREAL_TO_REAL(IN := RUNTIME("HMI SYS".Support.LastCycle_inout)); |

|

|

HBS Software Development |

|

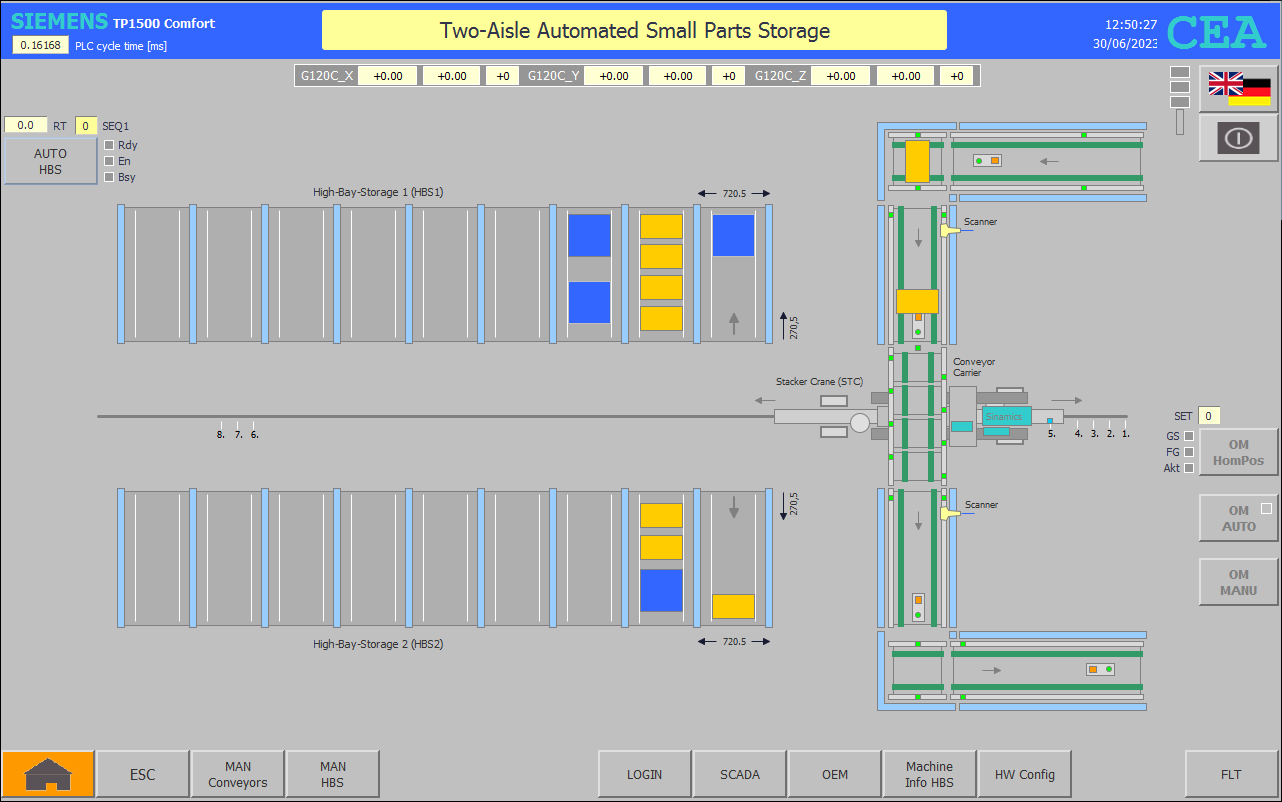

What you are seeing here is a section of the whole plant. Using standard TCP/IP protocol, the Material Flow Computer (MFC) defines the storage shelve, and the storage depth for each box that is to be stored in one of the high-bay storage warehouse. |