|

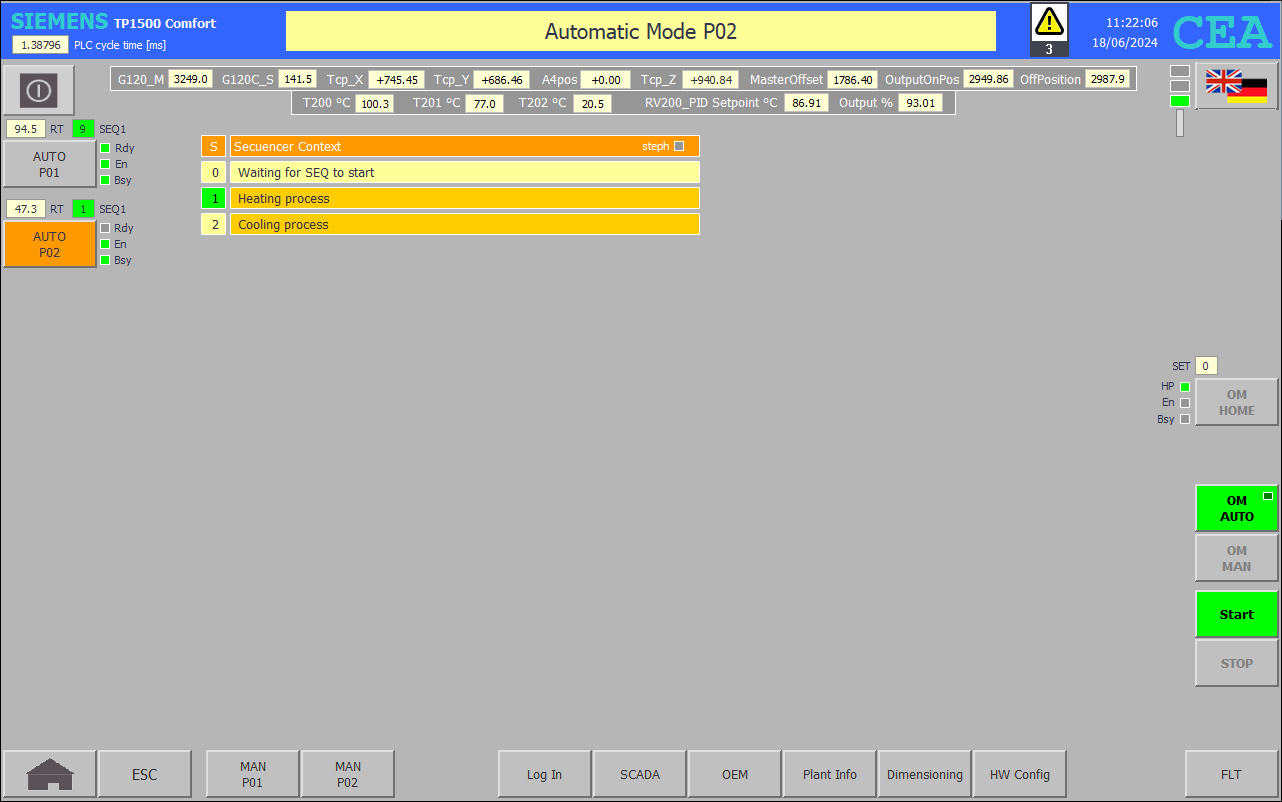

FB42 SEQ1 P02 : Heating Cooling |

|

|

|

|

|

Network 1: Show message on HMI "HMI KEY".Message.T201_PEW_Heating_Temperature_Reached := ABS("DI OUT P02".RV200_PID.Setpoint - "DI OUT P02".RV200_PID.Input) < "HMI KEY".SetValues."T201 Temperature_Deviation" AND "DI OUT P02".T201_PEW.Support.PEW_Scaled > 75.0; "HMI KEY".Message."T202_PEW Cooling_Temperature_Reached" := ABS("DI OUT P02".RV200_PID.Setpoint - "DI OUT P02".RV200_PID.Input) < "HMI KEY".SetValues."T201 Temperature_Deviation" AND "DI OUT P02".T202_PEW.Support.PEW_Scaled < 23.6 AND NOT "HMI KEY".Message.T201_PEW_Heating_Temperature_Reached; // Show on HMI RdyToStart "DI MAIN P02".M00.RdyToStart := "DI MAIN GLB".M00.HomPosSR AND "DI MAIN GLB".M00.AutoCmpltMa_run; |

|

|

|

|

|

Network 2: Define SSM last step #SSM(LAST_STEP := 2); |

|

|

|

|

|

Network 3: Step Switching Mechanism (SSM) CASE #SSM.S.stepact OF 0: // Waiting for sequencer to start "DI MAIN P02".M00.SEQ1_Busy := FALSE; IF #SSM.S.steps THEN #SSM.S.stepd := "DI MAIN P02".M00.RdyToStart; #RunTimeCounter := 0; END_IF;

1: // Heating process IF #SSM.S.steplo THEN "DI MAIN P02".M00.SEQ1_Busy := TRUE; // Assign actors pre-setting automatic mode "DI OUT P02".RV200_PID.Mode := 3; #SSM.S.c1.set := 100; "DI OUT P02".RV200_PID.ModeActivate := "HMI KEY".P02.RV200_PID.F12_Enable_WP; ELSE "DI OUT P02".RV200_PID.ModeActivate := FALSE; // Simulate suction V204 for 10sec #SSM.S.c1.start := "DI MAIN P01".M00.SEQ1_DoWP1; "DI OUT P02".M202.DRV.CmdExe_WP := "HMI KEY".P02.M202.F12_Enable_WP AND "DI MAIN P01".M00.SEQ1_DoWP1 AND #SSM.S.stepa; "DI OUT P02".E200.DRV.CmdExe_WP := "HMI KEY".P02.E200.F12_Enable_WP AND "DI OUT P02".M202.DRV.CmdExe_WP AND NOT #SSM.S.c1.done; "DI OUT P02".V204.VLV_O.CmdExe_WP := "HMI KEY".P02.V204.F12_Enable_WP AND "DI OUT P02".M202.DRV.CmdExe_WP AND NOT #SSM.S.c1.done; // Heating actors WP "DI OUT P02".V201.VLV_O.CmdExe_WP := "HMI KEY".P02.V201.F12_Enable_WP AND #SSM.S.stepa AND NOT #SSM.S.c1.done; "DI OUT P02".M200.DRV.CmdExe_WP := "HMI KEY".P02.V201.F12_Enable_WP AND #SSM.S.stepa AND NOT #SSM.S.c1.done; "DI OUT P02".V200.VLV_O.CmdExe_WP := "HMI KEY".P02.V200.F12_Enable_WP AND NOT "HMI KEY".Message."T201_PEW Heating_Over_Heated_whilst_Production" AND #SSM.S.stepa; // Calculate required temperature #SEQ400.SSM.S.steph := #SSM.S.steph OR NOT "DI OUT P02".M200.DRV.LampWP; #SEQ400.SSM.S.steps := #SSM.S.steps AND "DI OUT P02".RV200_PID.State = 3 AND "HMI KEY".P02.RV200_PID.F12_Enable_WP AND "DI OUT P02".V200.FB_WP AND "DI OUT P02".M200.DRV.LampWP AND "DI OUT P02".V201.FB_WP AND NOT "DI MAIN GLB".M00.TOF_CmpltMaOFF_Pulse.Q; #SEQ400(); "FC CALC PE UNITS"(PU_EXE := #SSM.S.stepa, PIPE_DN := 20.0, PIPE_LENGTH := 6.52, // meter HL_H := "HMI KEY".SetValues.FIT200_Hot_Water_Flow, TEMP_ACT_VAL := "DI OUT P02".T200_PEW.Support.PEW_Scaled, PU_SET_VAL := "HMI KEY".SetValues.Scal_PE_Unit_PU_SET_VAL, SET_POINT_TEMP => #Set_Point_Temperature, PU_ACT_VAL => #PU_Current_Value, TEMP_HOLD_TIME_SEC => #Temperature_Holding_Time); // sec "DI OUT P02".RV200_PID.Setpoint := #Set_Point_Temperature * "HMI KEY".SetValues.Scal_PE_Unit_Regulating_Factor; END_IF; "DI OUT P02".V202.VLV_O.CmdExe_WP := "HMI KEY".P02.V202.F12_Enable_WP; #SSM.S.stepd := "DI OUT P02".V202.FB_WP AND "DI OUT P02".M200.DRV.LampHP AND "DI OUT P02".V200.FB_WP AND "DI OUT P02".V201.FB_HP AND "DI OUT P02".V204.FB_HP AND "DI OUT P02".E200.DRV.LampHP AND #SSM.S.c1.done;

2: // Cooling process "DI OUT P02".RV200_PID.Setpoint := 2.0; // °C "DI MAIN P01".M00.SEQ1_DoWP1 := FALSE; "DI OUT P02".V202.VLV_O.CmdExe_WP := "HMI KEY".P02.V202.F12_Enable_WP; #SSM.S.c1.set := 70; #SSM.S.c1.start := "HMI KEY".Message."T202_PEW Cooling_Temperature_Reached"; "DI MAIN P02".M00.SEQ1_Done := #SSM.S.c1.done; "DI OUT P02".V203.VLV_O.CmdExe_WP := "HMI KEY".P02.V203.F12_Enable_WP AND NOT #SSM.S.stepd AND #SSM.S.stepa; "DI OUT P02".M201.DRV.CmdExe_WP := "HMI KEY".P02.M202.F12_Enable_WP AND "DI OUT P02".V202.FB_WP AND NOT #SSM.S.c1.done AND #SSM.S.stepa; END_CASE; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|