|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OB100 Start up : Complete restart entire plant |

|

|

|

|

|

Netzwerk 1: Limit Pre-Setting // Log-In run-time "DI MAIN GLB".M00.TON_Login.PT := t#120s; "DI MAIN GLB".#M00.ProductCounter.DlyOnReset.PT := t#1.5s; // +1-S120_M Deformable Rubber Winding Hub "DI OUT P01".S120_M.DRV.Support.SW_EndLim_MinPos := "+1-S120_M".Modulo.StartValue; // 0.0° "DI OUT P01".S120_M.DRV.Support.SW_EndLim_MaxPos := "+1-S120_M".Modulo.Length; // 5126.53° // +1-S210_S Rubber Steering Device "DI OUT P01".S120_S.DRV.Support.SW_EndLim_MinPos := -5.0; "DI OUT P01".S120_S.DRV.Support.SW_EndLim_MaxPos := 450.0; // TT Heating Oil "DI OUT P02".T200_PEW.Support.High_Lim := 170.0; // °C "DI OUT P02".T200_PEW.Support.Low_Lim := 0.0; "DI OUT P02".T201_PEW.Support.High_Lim := 145.0; // °C "DI OUT P02".T201_PEW.Support.Low_Lim := 0.0; // RV200_PID "DI OUT P02".RV200_PID.Support.ManualValue := 80.7; |

|

|

|

|

|

Netzwerk 2: HMI Set Values Pre-Setting "HMI KEY".SetValues.Temperature_Deviation := 5.5; "HMI KEY".SetValues.T201_Heating_Required_Temperature := 132.7; "HMI KEY".SetValues.Scal_PE_Unit_PU_SET_VAL := 20.0; "HMI KEY".SetValues.Scal_PE_Unit_Regulating_Factor := 1.65; "HMI KEY".SetValues.FIT200_Heating_Oil_Flow := 0.0; "HMI KEY".SetValues.Homing_Velocity := 30.0; |

|

|

|

|

|

Netzwerk 3: Tire Type (SCADA) "HMI KEY".Machine.Tire_Type1.Strap_Length := 71.84365; // meter "HMI KEY".Machine.Tire_Type1.Strap_Cross_Section := 54.4; // square mm "HMI KEY".Machine.Tire_Type1.Strap_weight := 5276.20; // gram // ---- "HMI KEY".Machine.Tire_Type2.Strap_Length := 105.40229; // meter "HMI KEY".Machine.Tire_Type2.Strap_Cross_Section := 54.4; // square mm "HMI KEY".Machine.Tire_Type2.Strap_weight := 7740.74; // gram // ---- "HMI KEY".Machine.Tire_Type3.Strap_Length := 75.23525; // meter "HMI KEY".Machine.Tire_Type3.Strap_Cross_Section := 43.52; // square mm "HMI KEY".Machine.Tire_Type3.Strap_weight := 4420.22; // gram // ---- "HMI KEY".Machine.Distance_to_CamStart := 3711.55; // mm |

|

|

|

|

|

Netzwerk 4: CAM_DISC Pre-Setting (SCADA) "DI OUT P01".CAM_DISC.CAM.MC_MeasuringInput.StartPosition := 0.0; "DI OUT P01".CAM_DISC.CAM.MC_MeasuringInput.EndPosition := 0.0; // full range "DI OUT P01".CAM_DISC.CAM.MC_CamIn.MasterSyncPosition := 0.0; "DI OUT P01".CAM_DISC.CAM.MC_CamIn.ApplicationMode := 0; // one plc cycle "DI OUT P01".CAM_DISC.CAM.MC_CamIn.MasterScaling := 1.0; // start factor before stretching "DI OUT P01".CAM_DISC.CAM.MC_CamIn.SlaveScaling := 1.0; // start factor before stretching "DI OUT P01".CAM_DISC.CAM.MC_CamIn.SlaveOffset := 0.0; "DI OUT P01".CAM_DISC.CAM.MC_CamIn.SyncDirection := 1; // positive, default=3 shortest war "DI OUT P01".CAM_DISC.CAM.MC_CamIn.MasterStartDistance := 1.0 "DI OUT P01".CAM_DISC.CAM.MC_CamIn.Velocity := -1.0; "DI OUT P01".CAM_DISC.CAM.MC_OutputCam.Direction := 1; // positive "DI OUT P01".CAM_DISC.CAM.MC_OutputCam.Mode := 1; // standard cam function |

|

|

|

|

|

Netzwerk 5: Support Cam Disc Measuringinput, CamIn, OutputCam "DI OUT P01".CAM_DISC.CAM.Support.SlaveModulo_StartValue := "DI OUT P01".S120_M.DRV.Support.SW_EndLim_MinPos; "DI OUT P01".CAM_DISC.CAM.Support.SlaveModulo_Length := "DI OUT P01".S120_S.DRV.Support.SW_EndLim_MaxPos; "DI OUT P01".CAM_DISC.CAM.Support.Cam_Shift_Distance := 10.0; "DI OUT P01".CAM_DISC.CAM.Support.Output_StartPosition := 10.0; "DI OUT P01".CAM_DISC.CAM.Support.Output_Distance := 400.0; |

|

|

|

|

|

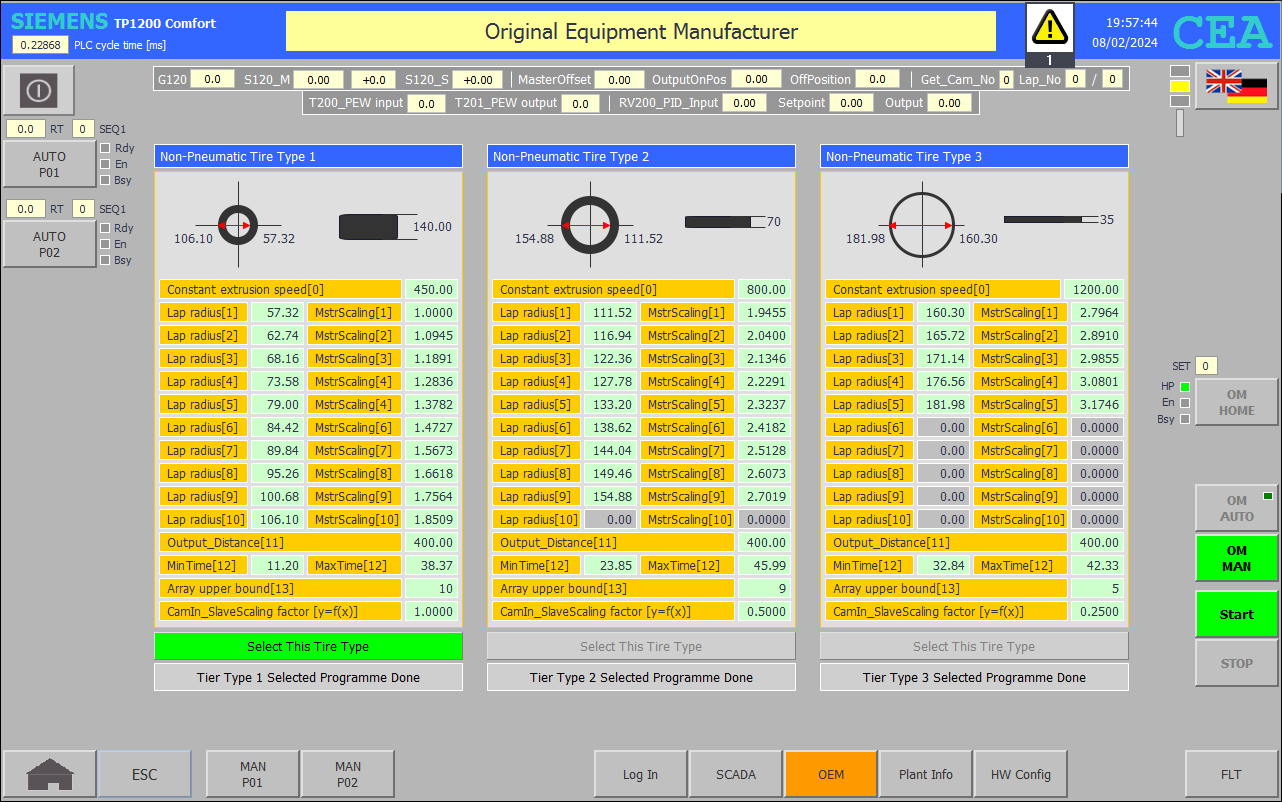

Netzwerk 6: Tire type 1 Extrusion speed 450.0 mm/s, Tyre width = 140.0 mm "HMI KEY".Machine.Tire_Typ1_Radius[0].Current_Value := 450.0; // extrusion speed mm/sec "HMI KEY".Machine.Tire_Typ1_Radius[1].Current_Value := 57.3248; "HMI KEY".Machine.Tire_Typ1_Radius[1].Scaling := 1.0; "HMI KEY".Machine.Tire_Typ1_Radius[2].Current_Value := 62.7448; "HMI KEY".Machine.Tire_Typ1_Radius[2].Scaling := 1.0945; "HMI KEY".Machine.Tire_Typ1_Radius[3].Current_Value := 68.1648; "HMI KEY".Machine.Tire_Typ1_Radius[3].Scaling := 1.1891; "HMI KEY".Machine.Tire_Typ1_Radius[4].Current_Value := 73.5848; "HMI KEY".Machine.Tire_Typ1_Radius[4].Scaling := 1.2836; "HMI KEY".Machine.Tire_Typ1_Radius[5].Current_Value := 79.0048; "HMI KEY".Machine.Tire_Typ1_Radius[5].Scaling := 1.3782; "HMI KEY".Machine.Tire_Typ1_Radius[6].Current_Value := 84.4248; "HMI KEY".Machine.Tire_Typ1_Radius[6].Scaling := 1.4727; "HMI KEY".Machine.Tire_Typ1_Radius[7].Current_Value := 89.8448; "HMI KEY".Machine.Tire_Typ1_Radius[7].Scaling := 1.5673; "HMI KEY".Machine.Tire_Typ1_Radius[8].Current_Value := 95.2648; "HMI KEY".Machine.Tire_Typ1_Radius[8].Scaling := 1.6618; "HMI KEY".Machine.Tire_Typ1_Radius[9].Current_Value := 100.6848; "HMI KEY".Machine.Tire_Typ1_Radius[9].Scaling := 1.7564; "HMI KEY".Machine.Tire_Typ1_Radius[10].Current_Value := 106.1048; "HMI KEY".Machine.Tire_Typ1_Radius[10].Scaling := 1.8509; "HMI KEY".Machine.Tire_Typ1_Radius[11].Current_Value := 400.0; // Start scaled Output_Distance "HMI KEY".Machine.Tire_Typ1_Radius[12].Current_Value := 11.20; // min time [sec] "HMI KEY".Machine.Tire_Typ1_Radius[12].Scaling := 38.37; // max time [sec] "HMI KEY".Machine.Tire_Typ1_Radius[13].Current_Value := 10.0; // array upper bound "HMI KEY".Machine.Tire_Typ1_Radius[14].Scaling := 1.0; // Slave scaling factor |

|

|

|

|

|

Netzwerk 7: Tire type 2 Extrusion Speed 800.0 mm/s, Tyre width = 70 mm "HMI KEY".Machine.Tire_Typ2_Radius[0].Current_Value := 800.0; // extrusion speed mm/sec "HMI KEY".Machine.Tire_Typ2_Radius[1].Current_Value := 111.5248; "HMI KEY".Machine.Tire_Typ2_Radius[1].Scaling := 1.9455; "HMI KEY".Machine.Tire_Typ2_Radius[2].Current_Value := 116.9448; "HMI KEY".Machine.Tire_Typ2_Radius[2].Scaling := 2.0400; "HMI KEY".Machine.Tire_Typ2_Radius[3].Current_Value := 122.3648; "HMI KEY".Machine.Tire_Typ2_Radius[3].Scaling := 2.1346; "HMI KEY".Machine.Tire_Typ2_Radius[4].Current_Value := 127.7848; "HMI KEY".Machine.Tire_Typ2_Radius[4].Scaling := 2.2291; "HMI KEY".Machine.Tire_Typ2_Radius[5].Current_Value := 133.2048; "HMI KEY".Machine.Tire_Typ2_Radius[5].Scaling := 2.3237; "HMI KEY".Machine.Tire_Typ2_Radius[6].Current_Value := 138.6248; "HMI KEY".Machine.Tire_Typ2_Radius[6].Scaling := 2.4182; "HMI KEY".Machine.Tire_Typ2_Radius[7].Current_Value := 144.0448; "HMI KEY".Machine.Tire_Typ2_Radius[7].Scaling := 2.5128; "HMI KEY".Machine.Tire_Typ2_Radius[8].Current_Value := 149.4648; "HMI KEY".Machine.Tire_Typ2_Radius[8].Scaling := 2.6073; "HMI KEY".Machine.Tire_Typ2_Radius[9].Current_Value := 154.8848; "HMI KEY".Machine.Tire_Typ2_Radius[9].Scaling := 2.7019; "HMI KEY".Machine.Tire_Typ2_Radius[11].Current_Value := 400.0; // Start scaled Output_Distance "HMI KEY".Machine.Tire_Typ2_Radius[12].Current_Value := 23.85; // min time [sec] "HMI KEY".Machine.Tire_Typ2_Radius[12].Scaling := 45.99; // max time [sec] "HMI KEY".Machine.Tire_Typ2_Radius[13].Current_Value := 9.0; // array upper bound "HMI KEY".Machine.Tire_Typ2_Radius[14].Scaling := 0.5; // Slave scaling factor |

|

|

|

|

|

Netzwerk 8: Tire type 3 Extrusion Speed 1200.0 mm/s, Tyre width = 35 mm "HMI KEY".Machine.Tire_Typ3_Radius[0].Current_Value := 1200.0; // extrusion speed mm/sec "HMI KEY".Machine.Tire_Typ3_Radius[1].Current_Value := 160.3048; "HMI KEY".Machine.Tire_Typ3_Radius[1].Scaling := 2.7964; "HMI KEY".Machine.Tire_Typ3_Radius[2].Current_Value := 165.7248; "HMI KEY".Machine.Tire_Typ3_Radius[2].Scaling := 2.8910; "HMI KEY".Machine.Tire_Typ3_Radius[3].Current_Value := 171.1448; "HMI KEY".Machine.Tire_Typ3_Radius[3].Scaling := 2.9855; "HMI KEY".Machine.Tire_Typ3_Radius[4].Current_Value := 176.5648; "HMI KEY".Machine.Tire_Typ3_Radius[4].Scaling := 3.0801; "HMI KEY".Machine.Tire_Typ3_Radius[5].Current_Value := 181.9848; "HMI KEY".Machine.Tire_Typ3_Radius[5].Scaling := 3.1746; "HMI KEY".Machine.Tire_Typ3_Radius[11].Current_Value := 400.0; // Start scaled Output_Distance "HMI KEY".Machine.Tire_Typ3_Radius[12].Current_Value := 32.84; // min time [sec] "HMI KEY".Machine.Tire_Typ3_Radius[12].Scaling := 42.33; // max time [sec] "HMI KEY".Machine.Tire_Typ3_Radius[13].Current_Value := 5.0; // array upper bound "HMI KEY".Machine.Tire_Typ3_Radius[14].Scaling := 0.25; // Slave scaling factor |

|

|

|

|

|

Netzwerk 9: FehlerBits PID_Compact Simulation with PLCSIM 16#0800 "+2-RV200_PID".CycleTime.EnEstimation := "+2-RV200_PID".CycleTime.EnMonitoring := FALSE; // CycleTime.Value: Time frame applied variable for interrupt OB [sec] "+2-RV200_PID".CycleTime.Value := 0.1; |

|